QMX+ 160–6 m Multi‑Mode Transceiver

From unboxing to first QSO – a builder‑friendly step‑by‑step guide

1. Pre‑flight checklist

| Category | What you need | Notes |

|---|---|---|

| Documents | Latest assembly manual for your PCB revision (e.g. Rev 3 doc 3.05) and matching operating manual | Download from the QRP‑Labs QMX+ product page. |

| Tools | 25–30 W temperature‑controlled iron, flux pen, solder wick, fine side‑cutters, tweezers, #1 Phillips, TORX T6, ESD strap, magnifier, bright lighting | Six‑layer board & large ground planes need extra heat – plan accordingly. |

| Test gear | Current‑limited bench PSU (12 V / 1 A), DMM, 50 Ω dummy load, watt‑meter or RF power probe, frequency counter or calibrated SDR, USB‑C cable | Optional: oscilloscope or spectrum analyser for PA check‑out. |

| Consumables | 60/40 or Sn‑Ag‑Cu 0.7 mm solder, isopropyl alcohol, cotton buds | Keep the board squeaky‑clean as you build. |

Before you heat the iron:

- Clear a static‑safe bench and brew decaf – shaky hands ≠ happy solder.

- Inventory every part against the BoM; contact QRP‑Labs immediately if anything’s missing.

- Read the manual twice, then watch a build video or two for extra context.

2. Board‑level assembly (main PCB)

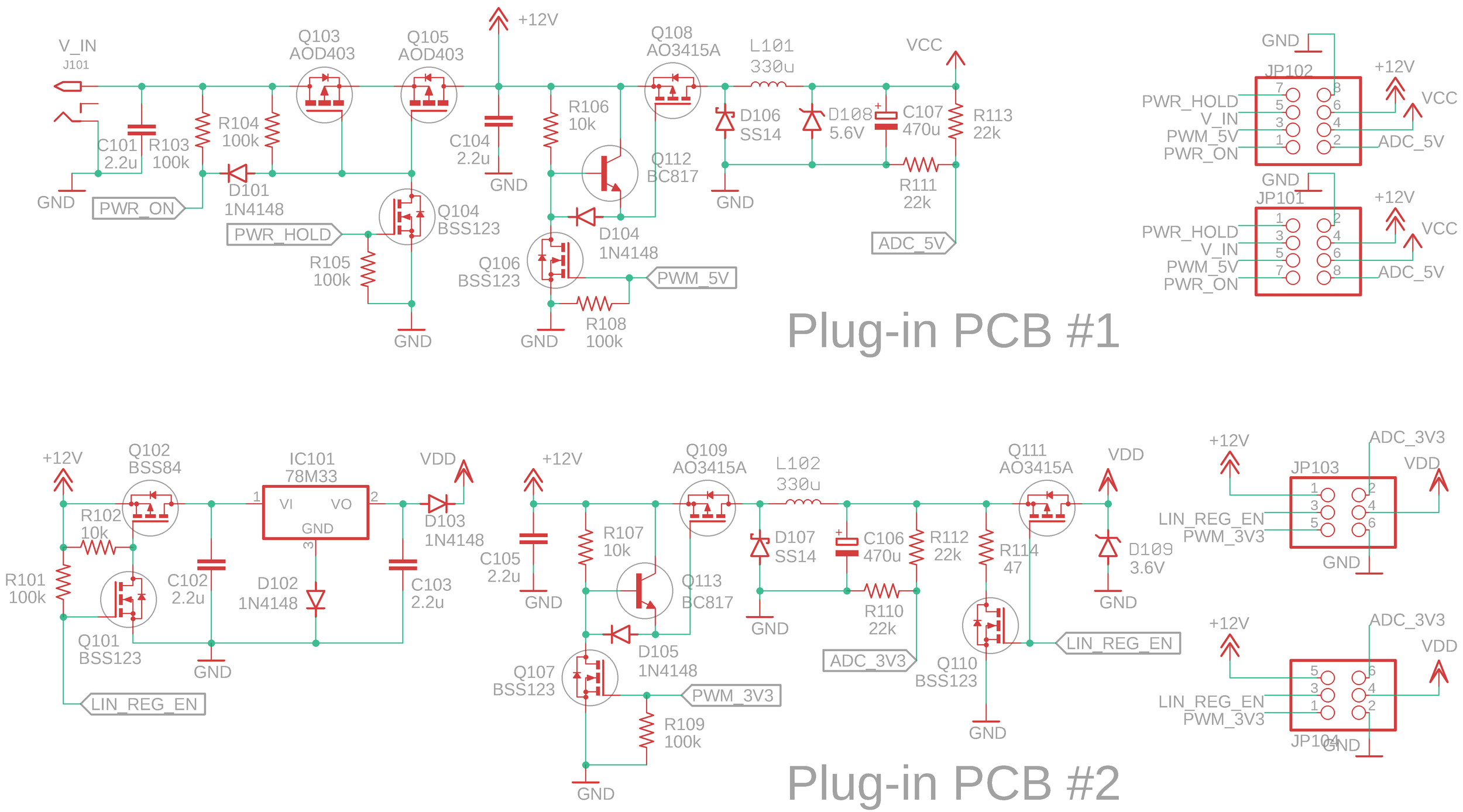

- SMPS daughter‑boards – align headers perfectly; re‑flow any dull factory joints.

- Low‑profile through‑hole parts – resistors, small caps, diodes. Work left‑to‑right, top‑to‑bottom.

- Toroids & transformers

- Wind exactly to the turn count in the manual; keep turns tight and evenly spaced.

Strip enamelby dragging the wire through a molten solder blob before inserting – guaranteed bright copper every time.- Verify continuity with your DMM.

- Power‑train devices (MOSFETs, regulators) and all IC sockets.

- Heat‑sensitive parts last – crystals, TCXO, microphone capsule (if fitted).

The six‑layer PCB soaks heat. Builders report best results with a slightly larger chisel tip, plenty of flux and quick, decisive soldering. Wick excess solder before adding the next part.

3. Front panel & LCD

- Tack‑solder the 16‑pin LCD header, plug the LCD in dry and verify it sits perfectly flush; then complete the joints.

- Install encoders, push‑buttons and 3.5 mm jacks on the front side only – double‑check orientation; mis‑placing them is the #1 de‑soldering horror story.

- Thread the front‑panel PCB onto its spacers and tighten just finger‑snug; you’ll remove it again for cleaning.

4. First power‑up & firmware flash

- Set your PSU to 12 V, 0.5 A current‑limit.

- Hold the left encoder shaft while applying power; the LCD backlight should come up and the current settle around 80 mA RX.

- On first boot choose

QMX + 160–6 mso the MCU loads correct band data. - Connect USB‑C to your PC, run

qld‑flash(Windows/macOS/Linux) and load the latest firmware (≥ 1_02_002). Progress appears on the GUI; the rig reboots automatically.

5. Alignment & self‑test

| Step | What to do | Expected outcome |

|---|---|---|

| REFCAL | Menu → Tests → Cal TCXO → zero‑beat WWV 10 MHz or use the optional GPS module | Reading within ±0.5 Hz |

| PA bias | Menu → Tests → Bias adjust; set each band for 0.22 A at key‑down | 3–5 W into dummy load |

| Band sweep | Use the built‑in signal generator; monitor on a separate receiver | Spurs ≤ –50 dBc |

| SWR bridge | TX into 50 Ω load; SWR should read ≈ 1 : 1 | Confirms bridge wiring |

6. Button up the enclosure

- Clean the board with IPA, blow‑dry, then mount the chassis rails.

- Slide the PCB into the extruded case; use nylon washers under the BNC and GPS SMA to avoid scratching the panel.

- Install the dev‑board or QLG3 GPS now if you ordered them.

7. Getting on the air

- CW / keyer – internal iambic keyer with memories; menu‑select paddle or straight key.

- Digital – one USB cable to WSJT‑X/JS8Call/etc. Choose the built‑in sound card, set CAT to Kenwood TS‑480, 115 200 baud.

- (Soon) SSB – firmware 1_03 adds full voice‑mode with CESSB processing; mic plugs into front‑panel 3.5 mm TRRS.

8. Popular mods & extras

| Mod | Parts | Why / when |

|---|---|---|

| Internal 3 S 18650 pack & BMS | 3 × 18650, TP4056‑3S | 11 V rail = full 5 W portable; fits behind LCD. |

| ATU‑10 nano | ATU‑10 kit + ribbon | Slips into spare volume; use AUX PTT line. |

| Fan bracket | 40 mm whisper fan | Keeps PA cool on FT8 marathons. |

9. Troubleshooting cheat‑sheet

No LCD backlight

- Missed 12 V rail or reversed LCD header

- Verify +12 V on pin 2 of LCD

High TX current, < 1 W out

- Toroid leads not fully stripped or PA bias mis‑adjusted

- Re‑strip leads and realign bias

USB not recognised

- Solder bridge on MCU header

- Inspect under magnification and continuity‑test adjacent pins

Still stumped? Search the QRPLabs@groups.io archive – hundreds of builders have logged their fixes.

10. Final sanity & safety

- Always TX only into a 50 Ω load or tuned antenna.

- RF burns hurt – the PA heat‑spreader can reach 70 °C at full duty.

- Obey your local licence conditions; 5 W is QRP, but it can still cause interference.